Tech Support

Here is a list of our FAQs that will help our customers navigate our product setups and answer any questions they may have. Below that are a few drawings and schematics for assembly and protocols. For any further inqueries please contact us with the information at the bottom of the page.

FAQs

-

A: No. OEM’s (Original Equipment Mfgs.) please contact Regal Beloit (https:/www.regalbeloit.com/). Replacement motors and/or Upgrade Energy-Saving Retrofit Kits are available through Gexpro at +1 (513) 326-2134 in the US or BSR at +1(905) 670-3229 in Canada.

-

A: Read EC Motor Control Test Procedure. Perform this test procedure in addition to all tests and practices prescribed by the equipment manufacturer and your professional training.

-

A: 529413

-

A: Yes, if you are a bona fide equipment manufacturer and contractor, call us at +1(858)748-7359. For end users, and others needing Evolution Controls’ Products should contact Gexpro at +1 (513) 326-2100 in the US or BSR at +1(905) 670-3229 in Canada

-

A: No, the motor has to be programmed for Vspd mode. Most EC Motors are custom programmed by the equipment manufacturer. Many, especially in residential applications are not programmed for Vspd mode. Please contact Evolution Controls Inc. at 858-748-7359 to find out if the motor you are interested in will work with our controls.

-

A: Maybe. These motors are Vspd enabled for in-house testing by equipment manufacturers, and for very few commercial applications. Most X13s in production equipment will not be Vspd enabled. Be careful not to develop a Vspd application for an X13, just to find out you will not be allowed to use it in production!

Our EVO™/ECM-X13 controller allows a 0- +10V signal to step control a Regal Beloit X13 or Endura Pro ECM motor.

-

A: Our ECM-X13 controller was designed for this purpose. Information on the function of the controller can be found in the product list. Wiring instructions can be found here.

-

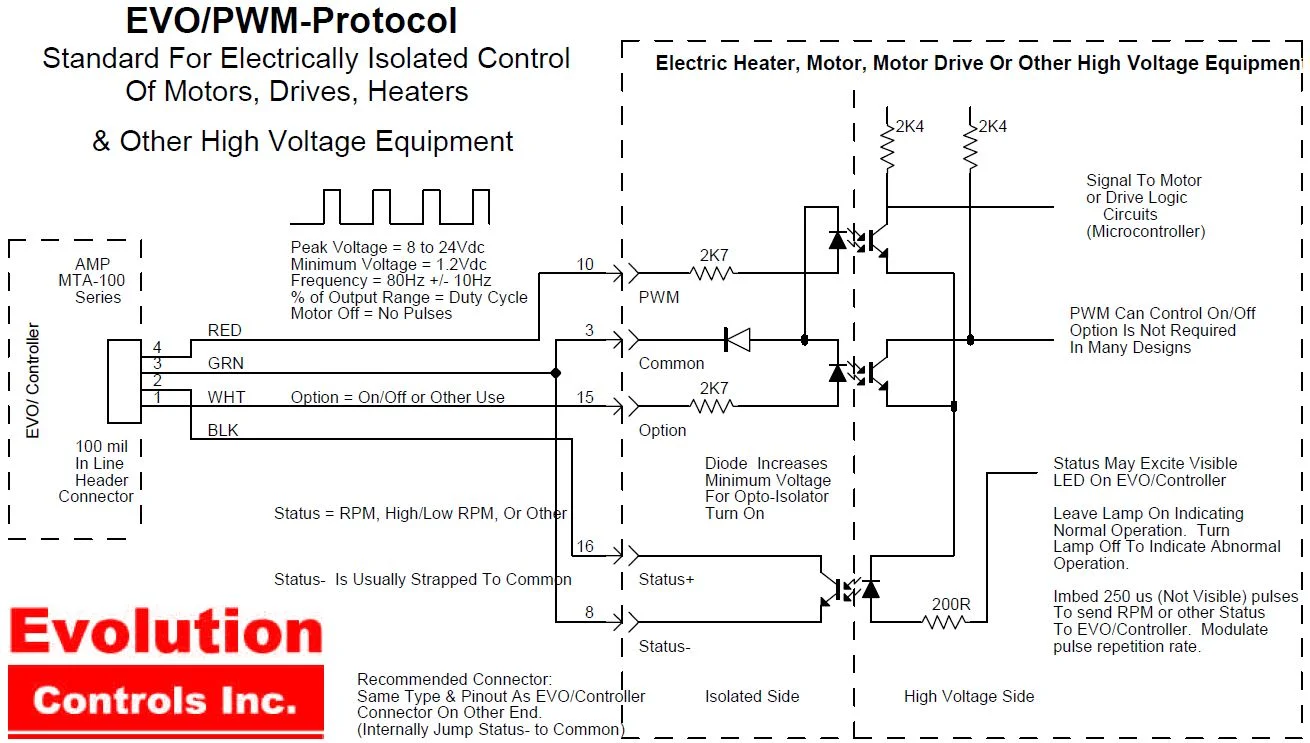

A: The standard pinout is 4 pins on an Amp MTA 100 header. Notice the solder pad (back of PC board) for the pins have three round pads and one square pad. The square pad is pin 1.

Go = Pin 1, Status = Pin 2, Common = Pin 3, and Vspd = Pin4.

Go = White, Status = Black, Common = Green, and Vspd = Red.

Go is used by some motors to signal the motor to run.

Status is an output from the motor that lights the red lamp on the EVO control and provides tachometer pulses to those EVO products having RPM feedback. Make sure the status output is programmed RPM only for EVO products having RPM feedback. Common is the common for the other three pins. Vspd is a PWM signal with 12.5ms duration and 22Vdc peak voltage for most EVO/ECM controls. Some special variations exist.

-

A: This problem is most often because the status output (Flag 7 for RB’s ECM 2.3 motor) is not programmed to RPM only.

-

A: This article covers the wiring between the EVO/™EC motor controllers and the Genteq® 142R motor for modulating motor speed control. Read the GENTEQ® 142R Wiring Guide.